Monitor, Measure & Action Flow Measurement

Related Products

BACKGROUND

Syrinix an award winning leader in providing intelligent pipeline solutions called upon the Processplus team to assist with flow measurement in a rather unusually located pipe line system.

The pipe line runs directly below one of Scotland’s busiest airport runways.

With up to 8 mega litres of water pumping through the aging pipe it was crucial the operator was able to monitor, measure and act upon any changes to the flow to avoid major incidents.

OBJECTIVE

Initial site survey was carried out whereby engineers were able to access the underground pipe and carry out flow measurement using an ultrasonic clamp-on flow transmitter whilst in the tunnel.

Syrinix were asked to provide a solution that would measure pressure transients, provide the data in an actionable format to ensure the pipes would not burst causing major network issues for the operator and the airport

CHALLENGE

After a site survey 2 locations were identified as the most suitable for the install, but both provided their own unique challenges as well as the obvious challenge of working with a 40 year old pipe system.

Whilst South Side location was the easier of the two installs, it did mean securing 25 metres of internal cabling in a protective conduit to run from the pipe.

North side location was even more challenging due to the proximity of the runway, the airport restrictions and the requirement to run 60 metres of cabling using 2 joint boxes one within the tunnel and one above ground so maintenance could be easier.

SOLUTION

Syrinix provided there Pipeminder instrument which records high resolution monitoring solution at 2 points on the pipe network.

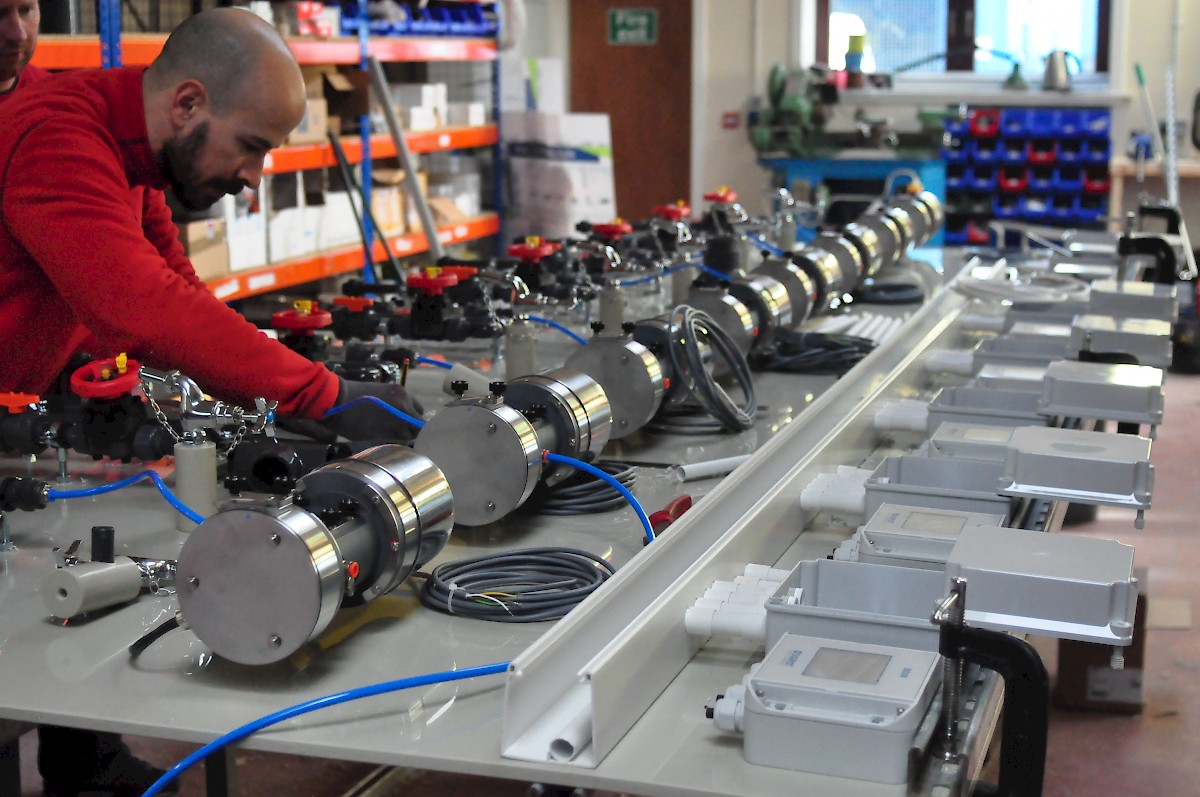

Processplus provided the Kat flow 100. A compact ultrasonic flow transmitter for permanent installation and flow measurement on single pipes. The varied functionality and simple operation of the KATflow 100 make it the perfect product for large projects and customer specific solutions.

Initial thoughts were the instruments would be installed in the pipe, but then the instruments would not be easily accessible to the operator.

A box panel was built in-house at Processplus HQ to house all the instruments in one place and then installed above ground with cabling running down into the pipe tunnel. The box was mounted on a frame which was then secured into the ground to a level consistent with other existing onsite equipment.